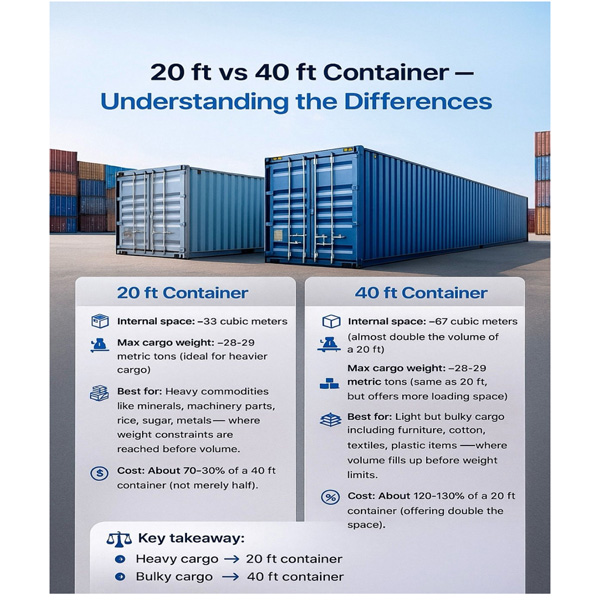

20ft vs 40ft Container--Understanding the Differencese for B2B import and export trade

In B2B international trade, choosing the right container size directly impacts logistics costs, cargo capacity, and supply chain efficiency. Below is a detailed comparison between 20 ft and 40ft export containers, tailored for B2B buyers to make data-driven decisions.

1. Standard Dimensions & Cargo Capacity

• 20ft Container (20GP): Exterior dimensions are approximately 6.06m (L) × 2.44m (W) × 2.59m (H), with an interior usable volume of about 28 cubic meters. It typically loads up to 28 metric tons of cargo, making it ideal for buyers dealing with small-batch, high-weight goods (e.g., machinery parts, metal products).

• 40ft Container (40GP): Exterior dimensions are around 12.20m (L) × 2.44m (W) × 2.59m (H), offering an interior volume of roughly 67 cubic meters—nearly double that of a 20ft container. Its maximum payload is about 26.5 metric tons (slightly less than 20ft due to structural weight), which suits B2B buyers with large-volume, low-weight shipments (e.g., textiles, furniture, consumer electronics).

2. B2B Logistics Cost Efficiency

• Per Unit Cost: For B2B transactions, 40ft containers have a clear advantage in per cubic meter cost. Shipping a 40ft container usually costs 1.5–1.8 times that of a 20ft one, but its volume is double, reducing the average logistics cost per unit of goods by 10–20%—a key factor for B2B buyers aiming to cut long-term supply chain expenses.

• Empty Space Risk: 20ft containers minimize empty space waste for B2B buyers with incomplete cargo batches. For example, if a B2B order only requires 30 cubic meters of space, using a 20ft container avoids paying for unused volume in a 40ft one, optimizing short-term shipping budgets.

3. B2B Supply Chain Adaptability

• Transport Flexibility: 20ft containers are lighter and more compact, making them easier to handle in regions with limited infrastructure (e.g., small ports, inland warehouses). This is critical for B2B buyers targeting emerging markets where logistics facilities may be less developed.

• Inventory & Delivery Cycles: 40ft containers align with buyers’ bulk procurement needs, such as seasonal stock-ups or long-term contracts. They reduce the frequency of shipments, lowering the risk of delays in B2B supply chains and ensuring stable inventory for downstream retailers or manufacturers.

4. Key Considerations for importer and Buyers

• Prioritize 20ft containers if your business focuses on small-batch, high-density cargo or serves markets with poor logistics infrastructure.

• Choose 40ft containers if your business operations involve large-volume orders, long-term contracts, or cost-sensitive bulk goods to maximize per-unit cost efficiency.